The advent of 3D printing has changed the face of product development and manufacturing.

Redington’s Digital & 3D Printing division brings designs to life through quality, innovation, and reliability. With a strong foothold in the 3D printing and 3D scanning industry, we have forayed into the business of on-demand part manufacturing under our commercial entity, Visuali. Visuali is changing the way product development and manufacturing professionals source small-quantity production and custom-designed parts. It is fully equipped to respond to custom requirements from anywhere in the world.

An approach to manufacturing that utilises computer systems to streamline and economise manufacturing services, supply chains, products and processes.

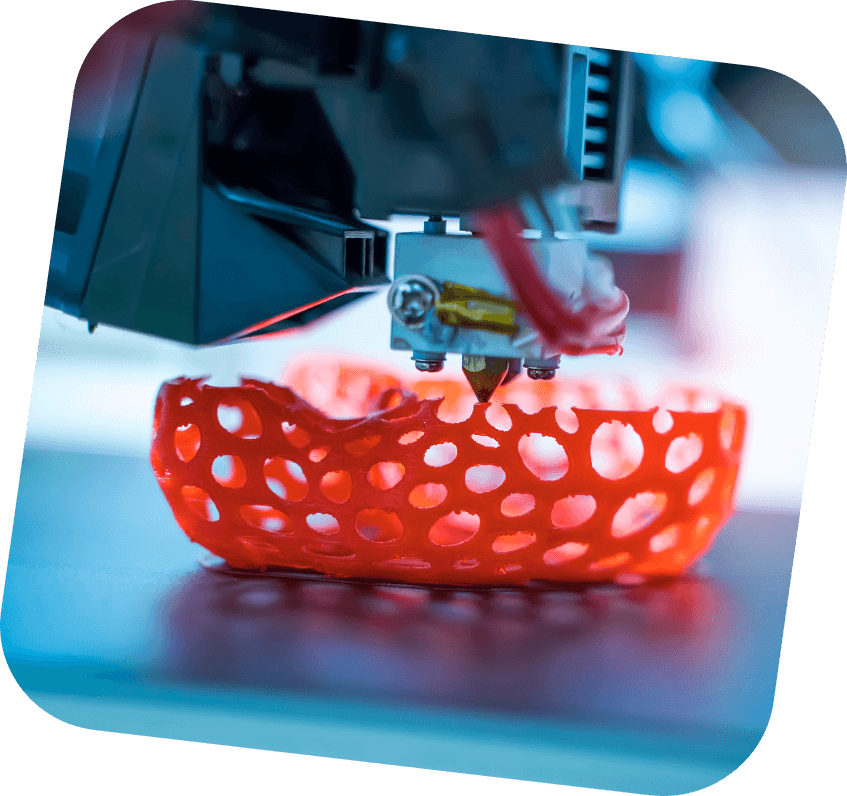

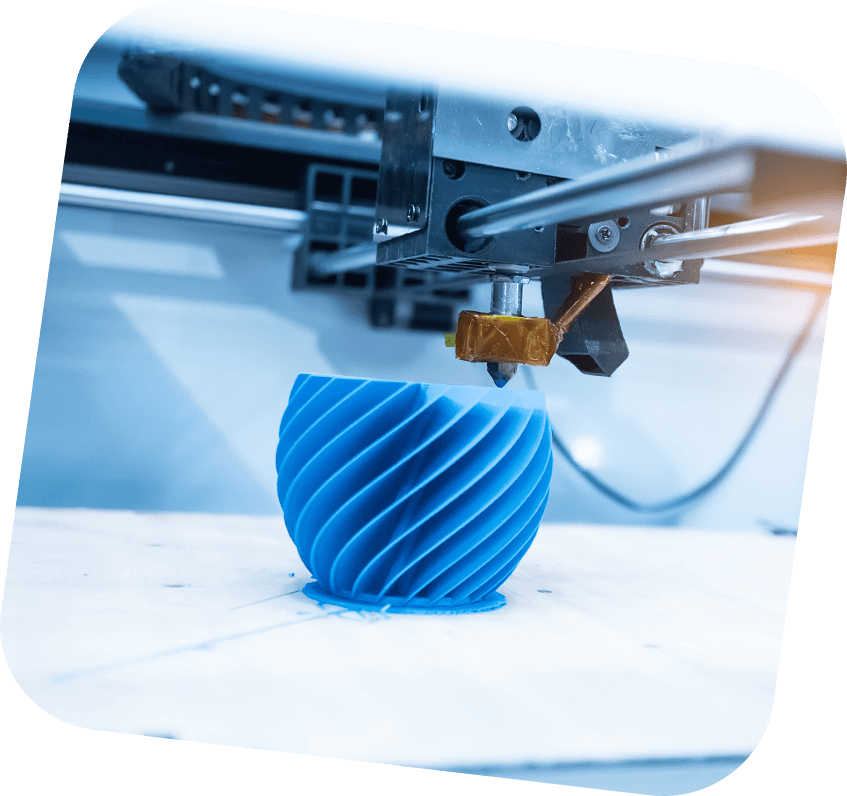

Prototyping in 3D printing is the physical conceptualisation of ideas and designs that accelerates manufacturing capabilities in a cost-effective manner.

Accelerating the widespread adoption of 3D printing and the digital transformation of the manufacturing sector, Multi Jet Fusion technology enables high build quality up to 10 times faster and at the lowest cost relative to competitive 3D printing solutions.

Binder jet 3D printing is widely regarded as the fastest additive manufacturing method for the production-volume output of highly dense and functional precision parts. Redington’s Binder jetting technology enables batch production, which helps manufacturers produce multiple versions of a single part in a single print, ultimately leading to cost savings and accuracy. With a native resolution of 1200 dpi, the Shop System is the highest-resolution single-pass binder jetting system available and is capable of producing as many as 670 million drops of binder each second. That precision makes it easy to create parts that feature incredibly fine details that would normally require expensive tooling.